Crystallisation allows the 3D structure of macromolecules to be revealed through X-ray diffraction. Instruct offer a fully automated crystallisation pipeline to achieve high-throughput with short crystallisation plate processing times, high reproducibility, and increased efficiency of the screening process.

Instruct has 10 centres offering Crystallisation across Europe. Navigate the map and click on the pins to discover centres near you.

Diffraction of single biological molecules is extremely weak so amplification is required if X-ray diffraction from conventional sources is used. This amplification can be achieved when three dimensional arrays of periodically repeated molecules, commonly called crystals, irradiated instead. The total scattering then becomes proportionally stronger with the increasing number of repeating unit cells.

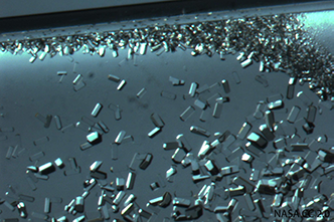

Crystals grow from supersaturated solutions. In macromolecular crystallography supersaturation is normally achieved by adding a precipitant to a concentrated solution of purified protein or macromolecule. A precipitant can be defined as any type of substance that would decrease the solubility of the sample without inducing denaturation. Neutral polymers, like different types of polyethylene glycol, salts or small organic acids are amongst the most common types of precipitants. However, crystal growth is a rare phenomenon and is very sensitive to the chemical and physical environment. Since the conditions that would lead to the formation of crystals can't be predicted, it is necessary to perform extensive screening experiments testing a series of different precipitants at different concentrations, at different pH and in the presence and absence of salts and other type of additives. Given the large number of parameters to be explored the capacity to perform large screening experiments is a critical factor for success in crystallisation. However other parameters external to the crystallisation experiment itself, like construct definition, sample purity and homogeneity are equally important.

Crystallising the protein molecule is thus a crucial step during the course of X-ray structure determination. Many attempts to ease the process using theoretical approaches have not been very helpful in practice; protein crystallisation is still a matter of trial and error and some practitioners consider protein crystallisation more of an art than a science. Over the last decade, structural biologists sought to overcome the bottleneck of growing well-diffracting protein crystals consistently for structure determination by putting the crystallisation process onto a more systematic and rational base, and by automating crystallisation and optimisation of screening conditions.

In the past crystallisation screening tended to consume large amounts of sample and time. However, this task has been notably advanced in the last years by the introduction of automated crystallisation systems. These systems can produce large numbers of experiments in parallel, but more importantly, they contribute to increase the efficiency of the screening process by reducing significantly the size of each individual experiment. It is possible to carry out extensive crystallisation screening experiments even when samples are available in very limited amounts. Projects that were traditionally considered to be beyond the reach of the crystallography technique, like those involving protein production in mammalian cell expression systems or the study of large multi-protein complexes, are accessible today.

Membrane proteins are traditionally difficult to produce and crystallise, due to their instability in solution. Instruct combines recently developed high throughput technologies for membrane protein production and crystallisation with the latest developments in X-ray diffraction data collection systems.